OS&D

How Lineage is Utilizing Kargo to Automate Warehouse Receiving

| Kargo | 4 min

What You Need to Know

The Case for Automating Receiving

Receiving is an essential but labor-intensive and time-consuming process in warehouse operations. Errors at this stage—whether due to fat-fingering or missed labels—can lead to inventory discrepancies, mis-rotation of lot-controlled products, shipment delays, and strained customer relationships.

That’s where automation can help. By combining advanced imaging with AI-powered data extraction, Lineage and Kargo are piloting new technology to improve automated receiving, enhancing both operational efficiency and inventory accuracy. In this post, we’ll dive into the challenges of automating receiving and how Lineage is utilizing Kargo’s patented computer-vision technology totackle them together.

The Challenge: Why Automating Receiving is Hard

Receiving has long been a challenging process in warehouse operations. It involves multiple steps, including inspecting the product for damage and other problems, recording information about the product entering the warehouse, and verifying that what the warehouse received is what the customer intended to send. Each of these must be executed with speed and precision to prevent downstream disruptions.

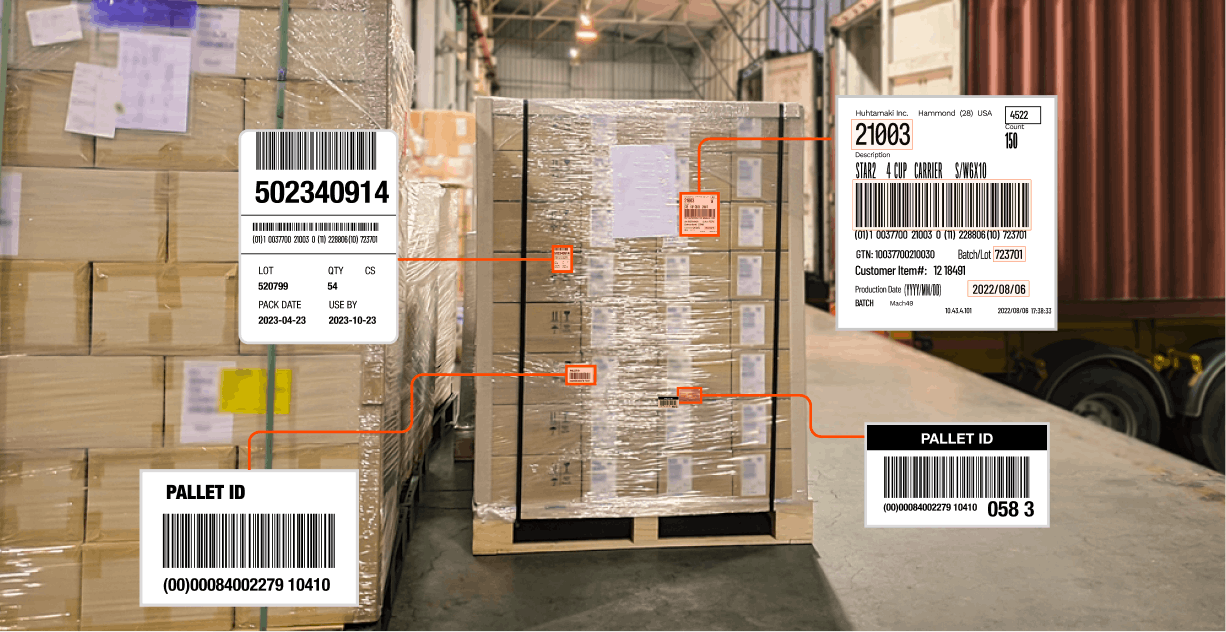

While automation presents a clear opportunity to enhance receiving by increasing speed and accuracy, it comes with two key challenges:

● Lack of standardization in pallet labeling. When you have thousands of customers, using unique formats, fonts, and layouts, traditional methods struggle to adapt, leading to inefficiencies and errors.

● Industrial conditions. Variable lighting, packaging, and inconsistent label placement can make it difficult to see and scan labels.

These challenges make automated receiving a problem that few solutions have been able to tackle—until now.

Solving Automated Receiving Together: The Lineage Eye + Kargo

The Role of Computer Vision in Automating Receiving

Computer vision is the key to automating receiving. Computer vision, a type of artificial intelligence (AI), enables machines to “see” or interpret and understand visual inputs.

In the context of receiving, computer vision can be used to extract information from images of pallets, including label data and the condition of freight. This enables the automation of critical processes like receiving and damage detection.

However, this is easier said than done. First, you need to capture high-quality images in a highly variable environment. Then, you need to extract the right information from those images, including from counting cases and from reading various unique labels. That’s why Lineage teamed up with Kargo to automate receiving with computer vision.

The Lineage Eye: Capturing Detailed Pallet Images

The Lineage Eye captures high-quality images of freight in a warehouse environment. Built by Lineage’s data science team, the Lineage Eye is equipped with high-resolution cameras and special lighting to capture detailed images of pallets. Once images of a pallet are captured, Kargo uses computer vision to extract important data from those images and flag errors or inconsistencies in real-time.

However, customer labels aren’t consistent from one customer to the next. This makes it difficult to understand what a given label says about the pallet’s contents.

Kargo: Using AI to Read Any Customer’s Labels

Kargo’s patented AI-driven label reading method is purpose-built for this task. By creating templates for each label type, Kargo’s method can interpret data accurately and efficiently, regardless of font, language, or layout. Kargo's AI approach stands out for its ability to rapidly process data from images of labels with high accuracy.

Lineage Eye + Kargo: Two Innovative Technologies Working Together

Together, the Lineage Eye and Kargo create an enhanced automated receiving solution. The Lineage Eye’s computer vision technology captures images of each pallet, while Kargo’s AI identifies, processes, and extracts data from the product labels on those images.

Automating critical receiving processes with the Lineage Eye and Kargo enables more throughput and greater efficiency at Lineage cold storage facilities.

The Benefits of Automating Receiving

The impact of automated receiving reaches across warehouse operations, influencing everything from labor to inventory management. It can create a ripple effect of improvements including:

● Enhanced operational efficiency: Automating receiving cuts down the number of labor hours needed to scan in pallets, reducing truck turn times and increasing throughput.

● Increased inventory accuracy: Fewer errors in data capture improves inventory accuracy, which contributes to better decision-making and more efficient supply chains.

● Improved labor utilization: Automation reduces the need for repetitive, manual tasks, freeing up team members for more strategic roles.

Conclusion: Setting a New Standard in Cold Chain Logistics

The program Lineage and Kargo are piloting demonstrates how both companies are working to modernize the industry. By combining advanced imaging with AI-driven data capture and processing, the Lineage Eye and Kargo are advancing automating warehouse receiving—making it faster, more accurate, and more efficient than ever before.

Ultimately, this achievement highlights how technological advancements are not only improving operational efficiency and accuracy,but also driving a broader transformation in the way warehouses operate and tackle challenges.

Questions?

Connect With us

Ask us anything or drop your email to stay in touch