Kargo System

Guide to Automated Dock Door Scanning: What You Need to Know

| Kargo | 3 min

Why Automate Dock Door Scanning?

- Cut Labor & Reassign Talent

Kargo’s scanner-less workflow captures data automatically, freeing auditors to focus on value-added tasks instead of repetitive scanning. - Increase Throughput

Towers record 350 MP of imagery per dock door and read 0.25 mm barcodes as a forklift drives straight through—no stopping, no bottlenecks. - Eliminate Mis-Shipments

Real-time exception alerts on embedded tower screens flag SKU or lot mismatches before the trailer leaves. - Real-Time ASN Receiving

Captured data posts to your WMS within seconds, creating touch-free inbound receipts and reducing check-in delays. - Strengthen OS&D Claims

High-resolution images and 4K video provide irrefutable evidence for damage or shortage disputes.

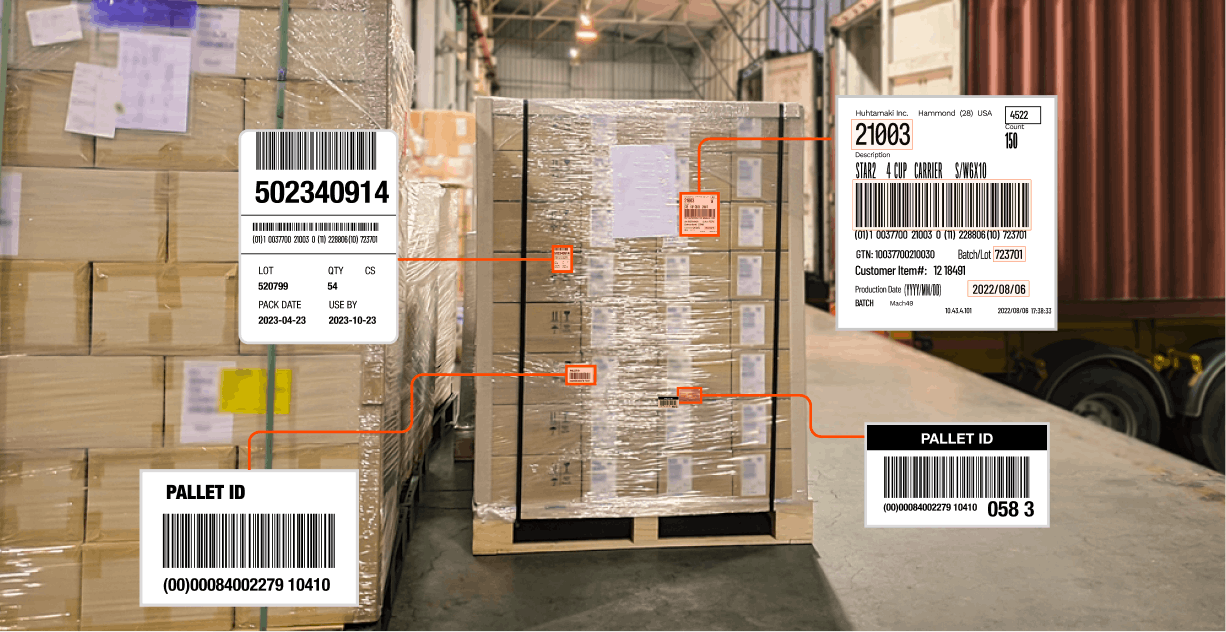

Data Requirements for Dock Door Scanning

Data Element

Why it Matters

License Plate Number (LPN)

Primary pallet identifier for WMS/ERP integration

SKU / Item Code

Drives inventory accuracy & order allocation

Lot / Batch / Expiry

Enables traceability & FEFO rotation

Quantity

Confirms pick accuracy

Timestamp & Dock ID

Links movement to a specific door & shift

Condition Images

Closes the loop on quality and damage detection

Kargo advantage: Patented OCR reads multiple labels simultaneously while AI models score damage with 99.9% accuracy. Learn more on the Kargo Towers.

Pictures & Video in Automated Dock Door Scanning

For high-value or perishable freight, still images are often insufficient. Kargo records continuous video, so you can scrub to the exact second a pallet crossed the threshold.

Where Does the Data Live in Dock Door Scanning?

Labels are rarely uniform—your system must handle variability.

- Master vs. Case Labels – Master labels may only contain a serial number. Kargo’s AI backfills item-level data by reading case labels when the pallet is mixed.

- Redundant & Irrelevant Labels – Computer vision filters out obsolete supplier labels to avoid false reads.

- Placement & Orientation – Forklift drivers aren’t printers; labels appear at different heights and angles. Kargo Towers capture 77 ft³ of volume, ensuring 360° coverage.

- Barcode & Font Size – Changing label formats is costly; instead, choose hardware (e.g., 40 MP/80 MP sensors) that resolves sub-millimeter bars at 8–12 ft.

Latency & System Response for Automated Dock Door Scanning

If downstream logic (e.g., hold / release) depends on scan results, aim for sub-second round-trip data flow from camera → analytics → WMS. Kargo pushes events in real time and flashes a green/red light to the driver so they never guess whether they are cleared to proceed.

Physical Environment Factors That Affect Dock Door Scanning

Question

What to Check

Mitigation

Forklift Speed

Typical drive-through speed (mph)

Tower shutter & exposure tuned for motion; Kargo Lift rides on the mast for mobile capture.

Pallet Wrap & Glare

Stretch film reflectivity

Cross-polarized lighting & AI glare removal

Lighting Conditions

Daylight, backlight, overnight shifts

Integrated LED arrays maintain consistent lux

Door Height & Width

Coverage area

Multi-camera array captures full envelope

Network & Power

Wi-Fi / LAN availability

Towers run on a single 110V drop; Lift draws power from forklift battery

Ready to See Automated Dock Door Scanning in Action?

Kargo Towers and the mobile Kargo Lift combine ruggedized hardware with edge-AI to turn every pallet movement into clean, structured data—no scanners, no slow-downs. Visit kargo.ai to book a live virtual tour or request a dock-side pilot.

Bottom Line: Automated dock door scanning isn’t an IT project—it’s an operational lever to unlock throughput, accuracy, and traceability at the same time. Start with data requirements, validate environmental fit, and partner with technology purpose-built for dock door scanning.

Questions?

Connect With us

Ask us anything or drop your email to stay in touch