OS&D

What Is OS&D (Overages, Shortages & Damages) and How to Prevent It with Automated Pallet Scanning

| Kargo | 4 min

What You Need to Know

Quick definition: OS&D stands for overages, shortages, and damages—the three most common freight mistakes that trigger costly customer claims.

Industry studies show that about 1.9 % of palletised shipments arrive with an OS&D issue¹, costing North-American shippers over $1 billion a year in fines, write-offs, and lost trust². This article explains why OS&D happens, how it hurts the bottom line, and the different tools—manual checks, barcode/RFID, dimensioning tunnels, and computer-vision towers—companies use to fight back. If you lead warehouse operations, logistics, or quality teams, you’ll learn practical steps to prevent OS&D and see where Kargo’s automated pallet-scanning system fits among the options.

How OS&D Creeps Into Everyday Warehouse Life

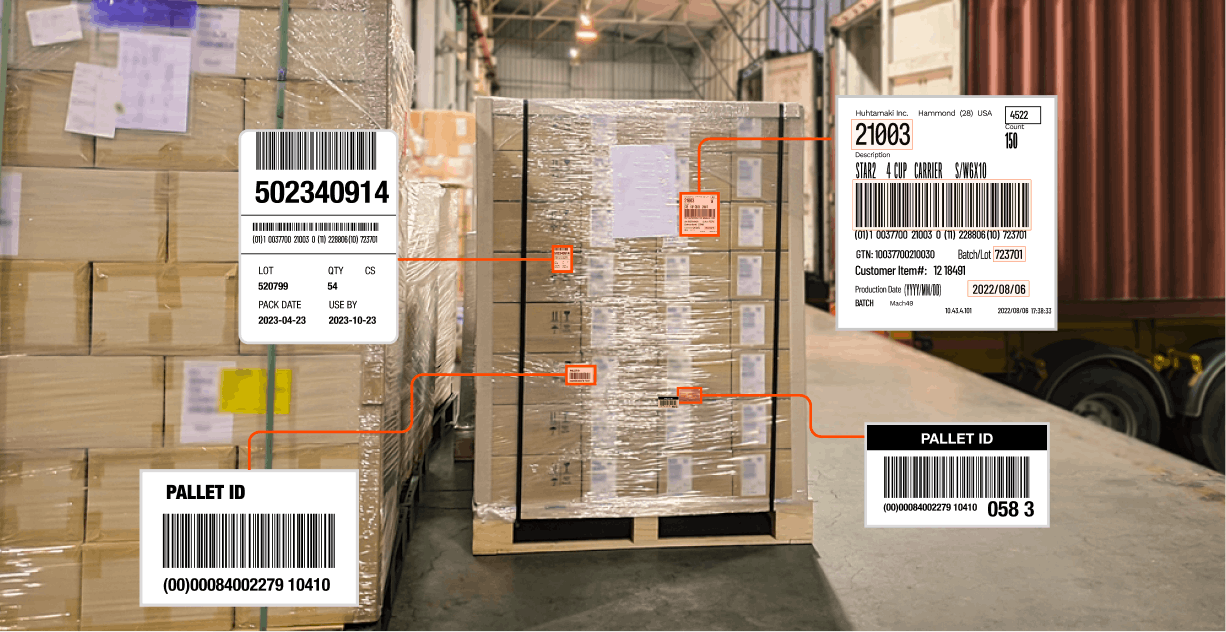

OS&D usually shows up in three places. First is receiving: a supplier may send ten pallets but one arrives crushed or missing; if your receiver signs the POD without proof, the cost is yours. Next is in-transit handling: a freight forwarder might re-stack pallets and tear shrink-wrap, so damage surfaces at the customer’s dock and fingers point back to you. Finally, outbound loading can hide shortages—maybe nine pallets are scanned but paperwork shows ten, and the gap isn’t discovered until the retailer files a claim weeks later. Manual data entry, rushed scans, and poor label visibility magnify these errors. Over 50 % of freight claims are rejected because required documentation—often photographs—is missing².

Most OS&D stems from everyday human error during loading or unloading. Labels tear, bills of lading vanish, counts get scribbled in a hurry, and dock cameras often miss the critical PO or SKU details. Tight schedules reward speed over accuracy, so small mistakes slip out the door and become expensive claims later. Automation can’t stop humans from making errors, but it can catch those errors before freight leaves the dock.

Why OS&D Happens (and Keeps Happening)Counting the Cost of OS&D

Most OS&D stems from everyday human error during loading or unloading. Labels tear, bills of lading vanish, counts get scribbled in a hurry, and dock cameras often miss the critical PO or SKU details. Tight schedules reward speed over accuracy, so small mistakes slip out the door and become expensive claims later. Automation can’t stop humans from making errors, but it can catch those errors before freight leaves the dock.

Counting the Cost of OS&D

The direct cost appears as chargebacks that span from the hundreds to hundred thousands. Indirectly, OS&D drains labor; one survey found supply-chain professionals spend nearly 14 hours every week manually tracking down data and many times its claim evidence and tracking data⁴. Repeated disputes erode hard-won relationships, nudging customers toward more reliable suppliers. In regulated sectors like food, damaged or missing products also invite FDA or FSMA scrutiny and potential fines.

Where Kargo Fits—and Why We Built It This Way

Kargo’s towers capture video of every shipment and barcodes, text, and more each time a pallet crosses the dock threshold. The footage syncs automatically with your WMS or TMS, so a claim can be answered in under 60 seconds without rummaging for clipboards.

In live deployments, customers report up to 34 % faster dock throughput and thousands of prevented errors per year.

Frequently Asked Questions

How long do I have to file a freight claim?

Most carriers follow NMFTA rules, giving you up to nine months from delivery, but always verify your bill of lading.

Is video evidence accepted in court?

Yes. Carriers and insurers increasingly accept timestamped footage as primary proof, provided the label and pallet integrity are clear.

What if my warehouse already uses handheld scanners?

Kargo complements them by adding visual confirmation. Many facilities start with both systems and later scale back manual scans on high-volume lanes once confidence grow.

Compliance & Regulatory Notes

Even hidden OS&D can spark compliance trouble. NMFC Item 222 details packaging liability, OSHA 1910.178 governs fork-truck handling, and the FSMA Food Traceability Rule mandates additional records by Jan 20 2026 for certain foods. Staying ahead of these rules reduces both charge-backs and audit headaches.

Next Steps for Reducing OS&D

Begin with a benchmark: compare your current claim rate against the ≈2 % industry baseline¹. Review how many outbound loads leave with both barcode and photographic proof, then pilot automation—whether barcode tunnels, RFID portals, or computer vision—on a single dock lane. Our 48-hour on-site trial lets you measure claim reduction in real conditions. If you’re ready, book a 20-minute walkthrough or explore our guide on supply-chain visibility tools.

Sources

- Commercial Carrier Journal, “Study highlights costs of underutilized truckload space and inefficiencies in LTL shipping” (May 30 2024)

- FreightClaims.com, “The $1 Billion Freight Claims Problem (and How to Fix It)” (May 28 2025) — >50% of claims rejected; >$1 billion annual cost

- First Call Logistics, “Avoiding Supply Chain Chargebacks” (Jul 31 2023)

- Supply & Demand Chain Executive, LeanDNA/Wakefield survey (Mar 5 2024)

Questions?

Connect With us

Ask us anything or drop your email to stay in touch